How it all began

Schönborner Armaturen GmbH can look back on its origins in 1992. At that time, we acquired a former forester’s house with a barn, stables and residential building in the municipality of Schönborn in the heart of Brandenburg. Under the management of the then managing directors Heidrun Dienst and Liane Ebert, the site was converted into a modern company building – a decisive step towards establishing a high-performance site for steel cutting and processing.

In 2002, Mr. Thomas Ebert took over the shares from Mrs. Dienst and initiated a new phase in the company’s development, in particular by expanding international business relations. Today, we are also established on the international market as a manufacturer and supplier of high-quality fittings accessories for the gas, water and waste water industry.

Thanks to the cooperation with the Technical University of Chemnitz and the BTU Cottbus, we then also took great steps towards independence in terms of research and production of our own products. From a small two-man business, which initially only dealt with the pure machining and processing of metal, we developed into an innovative research centre with our own Schoenborner brand products.

After moving to the Hennersdorf site, we also expanded our capabilities in terms of CNC processing and plastics processing to such an extent that today we are no longer dependent on the supply of external producers. All our products bear our in-house stamp. But this is not the only thing that makes us unique. We are the only company in Germany to offer our customers the possibility of putting together their own individual product in a configurator, supplemented by the 3D printing process, and to view the resulting solution even before it is actually realised.

In the near future, we would like to continue to drive these advances in the area of digitalisation and Industry 4.0 and build a centre of excellence for product configuration with innovative ideas.

Would you like to find out even more about us? Then just take a look at our entire company chronicle.

You will see: Science and business go hand in hand at our company.

1992

In 1992, Mrs. Heidrun Dienst and Mrs. Liane Ebert laid the foundations of our current medium-sized company, Schönborner Armaturen GmbH, in the municipality of Schönborn in the Elbe-Elster district of Brandenburg. At that time, they started with two employees. A little later, you bought the adjoining property of an old forester’s house with barn, stables and residential building. The stables and parts of the barn were used for storage and the old residential building was used to create recreation and social rooms.

1999

In 1999, the old forester’s house was demolished and work began on the construction of a new, modern company building. By converting and extending the old barn, space was gained for steel cutting and its processing.

2002-2003

In 2002, our company already consisted of 15 employees. During this time, Mr. Thomas Ebert took over the company shares from Mrs. Heidrun Dienst and did the first foreign business in Switzerland, France and later also in Scandinavia.

Furthermore, from 2003 onwards, we were able to win the TU Chemnitz as a strong partner in research and product development, with whose cooperation, for example, the hybrid coupling sleeve or a new brake and pull-out safety system were developed. Our company’s spirit of research was greatly inspired thanks to this cooperation, especially with Prof. Dr.-Ing. Wolfgang Nendel, deputy head and research area manager of the professorship “Plastics Technologies and Machine Design”. Since then, we have developed from a small two-man business with the occupation of purely working and processing metal, to an innovative research centre with our own products of the “Linkage manufacture” brand as well as other exciting innovations at home and abroad.

2006

In 2006, due to the rapid growth of our company, we moved to Hennersdorf to the former Hebel gas concrete plant. This factory was built in 1979-81, where our current company owner worked as an apprentice and later as a shift fitter. In the same year, we fundamentally optimised the quality of our material cuts as well as the effectiveness in the entire production with the acquisition of a CNC-controlled sawing/cutting system.

2007-2010

Nachfolgend haben wir uns immer stärker damit beschäftigt, wie wir unsere Fertigungstiefe weiter ausbauen können. In dieser Zeit begonnen wir nicht nur mit der Kunststoffverarbeitung, sondern schufen uns in der Lohnfertigung in den Bereichen der Automobilindustrie sowie dem Musikinstrumentenhandel ein zweites Standbein. Auch hier vollschritten wir bedeutende Meilensteine in Sachen Innovation dank der Zusammenarbeit mit der TU Chemnitz. Unsere Bauteile im Kunststoff-Spritzgussverfahren können wir seither eigenständig herstellen, was uns von der Belieferung externer Produzenten unabhängig macht. Um dabei ebenfalls unsere eigenen Werkzeuge zu entwickeln, diese zu warten und instand setzten zu können, begonnen wir nun auch im Bereich der CNC-Bohr-/Frästechnik sowie der CNC-Drehtechnik inkl. robotergestütztem Materialhandling unser Know-how auszubauen und damit unser Angebotsspektrum zu erweitern.

2012-2013

With 35 employees, we celebrated our 20th anniversary in 2012 and the progress we have made and the success we have achieved in customising and making the production of actuating elements for fittings in the municipal gas, water and wastewater industry more flexible. With our approximately 60 patents and utility models, we secured a leading position in the industry.

In 2013, we succeeded in gaining the BTU Cottbus as a research partner and for knowledge transfer, in addition to the TU Chemnitz. Spurred on by the Chemnitz cooperation and the successes achieved, we now pushed ahead with the first joint projects. Since then, we have realised 1-2 joint projects with our two research partners every year and have initiated well over 2 million euros to date.

2015

In 2015, we had our external appearance redesigned by the Finsterwalde advertising agency Die Piktografen. With a modern corporate identity, we show to this day that not only are our products unique, innovative and forward-looking, but that our entire company embodies this mission statement.

2016-2017

In 2016, we bought our previously rented premises and expanded them to a total size of 20,000m² and immediately started the expansion and renovation, which almost doubled the production area.

Spurred on by the vision of delivering a perfect product, we had our business processes audited. Since then, we have also been certified by TÜV SÜD Management Service for the development, production and distribution of fittings accessories for the gas, water and wastewater industry.

Our old homepage has had its day. On March 1st, 2016 the kick-off of our new web-optimized site took place.

2017

In October 2017 we looked back on 25 years of Schoenborner.A saw and a conventional lathe had to be sufficient to start production.Now the CNC department has 3 milling machines and 2 lathes. In the plastics department there are 2 injection molding machines and an extruder. The assembly department is equipped with 2 friction welding systems and individual workstations. Various workplaces are available for welding work. A new sawing system was installed.In addition to the management in the areas of sales, accounting, project management, production management, human resources, marketing, logistics and construction, 12 employees work in administration. 3 employees deal with digitization on the topics of configuration and 3D visualization.

2017-2018

The topics of Industry 4.0 and digitalisation are on our daily agenda. All the more so because our company owner is a member of the IHK IT and Innovation Committee and the DIHK Industry and Research Committee. In our search for a solution to minimise the enormously increased workload associated with the increasing personalisation of products and product features, we came across a corresponding software solution. The Jena-based company ORISA offered us the desired opportunity to bring the topic of product configuration to life. Since 2017, we have therefore been offering our customers the opportunity to submit their product enquiries via our website in a configurator and to put together their own Schoenborner brand product themselves. This solution has since become our greatest pride.

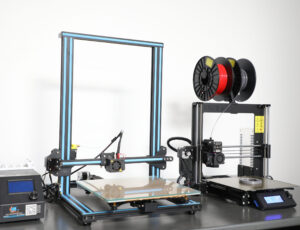

We no longer want to do without the 3D printing process we use in our daily work. It allows us to precisely create consumer samples in order to check their feasibility in terms of manufacturing processes. What is still far from feasible for some has long been standard for us. We thus offer every customer the visualisation of their own product idea before its actual production. To date, no other industry-related company in Germany offers comparable techniques, such a mature product variety and vertical range of manufacture as well as our associated competences.

In order to interest young people in our region in particular in such topics, we have made it our task to support the state of Brandenburg in the development of curricula for the training of trainers and the education of their apprentices based on this. But we also offer committed students the opportunity to write their final thesis at our company and to experience and help shape practical research.

2019

In 2019, we can look back on a small increase in the number of our employees, in which we were able to hire returnees to the district in our company, among other things. Our constant contact with the BTU-Cottbus/Senftenberg and the TU-Chemnitz has continued as in previous years and we are therefore still very much involved in research and development. We have also continued to develop technically, our design laboratory has been expanded with a 3D coordinate measuring machine, which enables us to measure parts quickly and precisely. Furthermore, we have joined the network “Water 4 All”, a project that is concerned with the protection and safeguarding of freshwater resources over several phases. We are pleased to report that a trainee from the BTU Cottbus/Senftenberg was allowed to travel to Australia to report on current and future projects of our company at a conference.

2020

This year was no normal year. A pandemic broke out across countries. The virus “Covid 19” restricted humanity in many areas of life, including the economy. Measures were developed and taken to contain the spread and thus the transmission of the viruses. While many companies had to cut jobs during this difficult time, we, as Schönborner Armaturen Gmbh, were able to hire more young qualified employees. Nevertheless, it was a premiere for us to send our administrative staff to the so-called “home office”, which was only one of many measures to counteract the virus.

Following the Corona protective measures, some employees moved their offices to our adjoining building. This is just one of several measures that we as the “Schönborner” company have taken to counteract the coronavirus.

Composites United e.V. (CU) is one of the world’s largest networks for fiber-based multi-material lightweight construction. Our managing partner Thomas Ebert will become a board member of the CU Ost cluster, which as a regional representation of interests connects around 60 companies and research institutions in the new federal states and thus bundles the fiber composite competencies in the region .

2021

Schönborner Armaturen GmbH has been awarded the “Germany’s Innovation Leader” certificate by the F.A.Z. Institute for the second time and is thus among the top 100 most innovative companies in Germany.

The Germany-wide study “Germany’s Innovation Leader” was carried out by Prognos AG on behalf of the F.A.Z.-Institut, a subsidiary of the Frankfurter Allgemeine Zeitung, in cooperation with the IMWF Institute for Management and Economic Research.

2022

This year, Schönborner Armaturen GmbH is awarded the Brandenburg Innovation Prize in the Metal Cluster by the Brandenburg Ministry of Economic Affairs for the “Leak Detection Test Bench” project. This is a result of the curiosity of our managing partner Thomas Ebert and his vision to develop the fire for research and development as well as innovation in as many employees as possible.

For the first time , Schönborner Armaturen GmbH is supporting two students from the Technical University of Applied Sciences Wildau with a Deutschlandstipendium each. Schönborner expects a synergy effect from the closer cooperation between the departments of engineering and natural sciences and the research and development department at Schönborner.

In August 2022, the Brandenburg Ministry of Economic Affairs has finally approved the application for the establishment and financial support of the innovation cluster “WasserWirtschaft”. The aim of the cluster is the use of innovative technologies and processes to minimize the consequences of climate change on water resources and their users.

2023

Like the entire German economy, Schönborner Armaturen GmbH struggled with the consequences of the war in Ukraine in 2023, which had a particularly negative impact on energy prices and supply chains.

Together with the Berlin-based company nanoLogika GmbH, we began to further develop the intuitive user interface of our product configurator for built-in fittings at the end of 2023, thanks to which the configuration process can now be implemented more efficiently. The configurator enables users to visualize the desired built-in fittings in real time, enter all the desired specifications and directly create a precise request for quotation or tender text.

Together with the Berlin-based company nanoLogika GmbH, we began to further develop the intuitive user interface of our product configurator for built-in fittings at the end of 2023, thanks to which the configuration process can now be implemented more efficiently. The configurator enables users to visualize the desired built-in fittings in real time, enter all the desired specifications and directly create a precise request for quotation or tender text.

2023 was a special year for our company – not only because of the successful projects and challenges we mastered, but also because of the expansion of our team with two international specialists. They quickly integrated into our corporate culture and made an important contribution to the success of our projects.

2024

We took a significant step in the further development of our technical equipment in 2024 with the acquisition of a further (8th) 3D printer. This powerful printer enables us to print complex components in high quality and with impressive attention to detail – and at high speed.

We took a significant step in the further development of our technical equipment in 2024 with the acquisition of a further (8th) 3D printer. This powerful printer enables us to print complex components in high quality and with impressive attention to detail – and at high speed.

This year, we were nominated for the Training Star 2024. This award, which is presented for outstanding commitment and exemplary performance in training, underlines the importance of our work in the area of recruiting young talent and training.

A particular highlight was the Future Congress in September 2024 at the Kulturweberei Finsterwalde, which was held in collaboration with Schönborner Armaturen GmbH and the Water Economy Innovation Cluster. The congress provided a valuable space for the exchange of ideas, best practices and visions between municipal network operators, scientific institutions and cluster members (companies from the private sector).

With the completion of the data and AI-supported early warning system (DAKI-FWS) project this year, a significant step was taken in the preventive detection of risks and the efficient analysis of data. The system uses modern technologies to react to potential dangers and irregularities in various areas at an early stage. The involvement of Schönborner Armaturen GmbH ensured that developed components are also used in the water industry.

With the completion of the data and AI-supported early warning system (DAKI-FWS) project this year, a significant step was taken in the preventive detection of risks and the efficient analysis of data. The system uses modern technologies to react to potential dangers and irregularities in various areas at an early stage. The involvement of Schönborner Armaturen GmbH ensured that developed components are also used in the water industry.

Our future

All of these measures, skills and visions are intended to help us build an innovative centre of excellence for product configuration and 3D visualisation in the near future. Following the digital transformation that can no longer be stopped and the networking of all processes in science and business, we want to shape the transfer of knowledge in the state of Brandenburg in a way that promotes the future and create the foundation for Industry 4.0 in the Lausitz region. Today, many specialist dealers, fittings manufacturers and municipal supply and disposal companies are already convinced of us and our capabilities.

Schönborner – Newsletter

Immer gut informiert auf dem neuesten Stand: Erfahren Sie als erster von innovativen Produkten und exklusiven Aktionen. Melden Sie sich zu unserem Newsletter an!

Deutsch

Deutsch