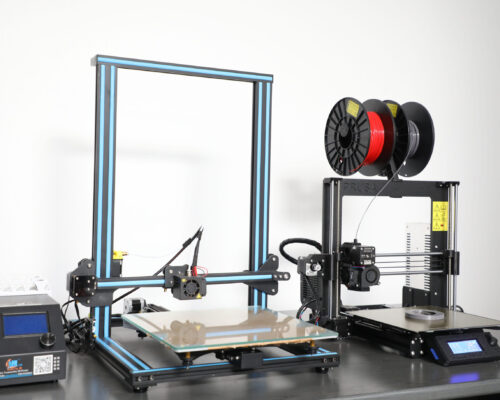

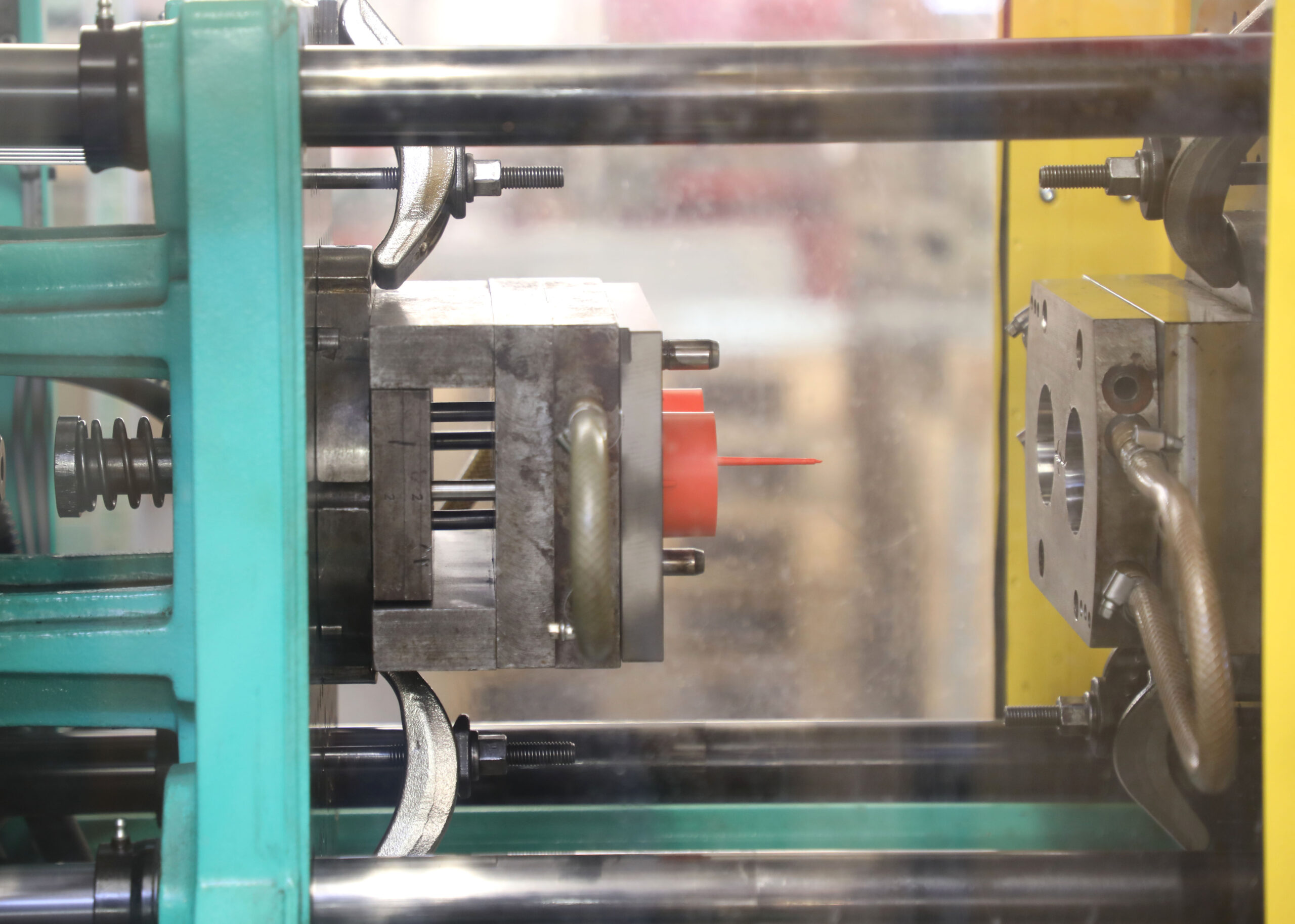

At the heart of our modern plastics department are two injection moulding machines from Arburg and an extruder for the production of plastic profiles. Furthermore, two 3D printers give us the advantage of producing prototypes from plastic.

We process all commercially available thermoplastics, but also glass fibre reinforced materials and WPC. With a clamping force range of 500 – 1,500 kN, we realise part weights of 4g – 200g in injection moulding, depending on the material. We extrude pipes in the diameter range up to approx. 70 mm. We offer the design and construction of the appropriate tool for your injection moulded part. With professional service we accompany you through all phases from product development to series production.

INJECTION MOULDING

ARBURG Allrounder 320 C

- 500kN Schließkraft

- 550mm maximaler Abstand zwischen den Werkzeugplatten

- 200mm minimale Werkzeughöhe

- 350mm maximaler Öffnungsweg

- 125mm maximaler Auswerferweg

- maximale Werkstückgewichte:

- PE-HD und PP ca. 38g

- PA 6.6 und ABS ca. 48g

- TPE ca. 45g

ARBURG Allrounder 470 C

- 1.500kN Schließkraft

- 750mm maximaler Abstand zwischen den Werkzeugplatten

- 250mm minimale Werkzeughöhe

- 500mm maximaler Öffnungsweg

- 175mm maximaler Auswerferweg

- maximale Werkstückgewichte:

- PE-HD und PP ca. 160g

- PA 6.6 und ABS ca. 205g

- TPE ca. 190g

EXTRUSION

Noris ESE 50

- 50 mm Schneckendurchmesser

- 1.400 mm Schnecklänge

- 60kg/h Leistung

- 0,8-8m/min Abzugsgeschwindigkeit

- Materialien: alle gängigen Thermoplaste

- maximale Querschnitte: Ø70x2mm

ADDITIVE MANUFACTURING

Additive Manufacturing

Schönborner – Newsletter

Immer gut informiert auf dem neuesten Stand: Erfahren Sie als erster von innovativen Produkten und exklusiven Aktionen. Melden Sie sich zu unserem Newsletter an!

Deutsch

Deutsch